Selecting Bag-In-Box (BIB) packaging materials suitable for jams and juices requires comprehensive consideration of factors such as product characteristics, shelf life requirements, taste protection, and cost-effectiveness. The following is a detailed analysis and suggestions:

1. Understand the characteristics of jams and juices

Jam: Usually has high viscosity and may contain pulp particles and sugar. The packaging material needs to be able to withstand its viscosity and particles while preventing sugar crystallization or precipitation.

Juice: Usually liquid, may contain vitamins, fructose and other ingredients, is sensitive to oxygen and light, and is easily oxidized and deteriorated. The packaging material needs to have good barrier properties to extend the shelf life.

2. Key material property requirements

(1) Barrier properties

Oxygen barrier properties: Juice and jam are easily deteriorated due to oxidation, so the packaging material needs to have good oxygen barrier properties. Commonly used barrier materials include multi-layer composite films (such as PET/PE, PA/PE, etc.), among which PET (polyethylene terephthalate) and PA (nylon) have excellent oxygen barrier properties.

Light barrier properties: Nutrients in juice (such as vitamin C) are sensitive to light, so the packaging material needs to have certain light-proof properties. You can choose a composite film with an aluminum foil layer or a dark plastic film.

(2) Chemical resistance and durability

The acidity of jam and juice may cause corrosion to the packaging material. Therefore, the packaging material needs to have good chemical resistance, such as using acid-resistant polyethylene (PE) or polypropylene (PP) as the inner layer material.

At the same time, the packaging material needs to be able to withstand mechanical pressure and temperature changes during transportation and storage.

(3) Sealing

The sealing of BIB packaging is the key to ensuring the shelf life of the product. The packaging material needs to work perfectly with accessories such as valves and tubes to prevent liquid leakage and air ingress. For example, using PE or PP films with good heat-sealing properties can ensure the sealing of the packaging.

(4) Taste protection

The packaging material should not react chemically with the jam or juice to avoid affecting the taste and flavor of the product. For example, the use of food-grade plastic materials (such as PE, PP) can avoid the generation of odor.

3. Selecting a suitable multi-layer composite film

Inner layer: The inner layer material that is in direct contact with the product is usually made of food-grade polyethylene (PE) or polypropylene (PP). These materials have good chemical resistance and odorlessness, and can protect the taste of the product.

Middle layer: The middle layer is usually used to provide barrier properties, such as PET or PA, which can effectively block oxygen and moisture.

Outer layer: The outer layer material needs to have good printing performance and mechanical strength, usually polypropylene (PP) or polyester (PET).

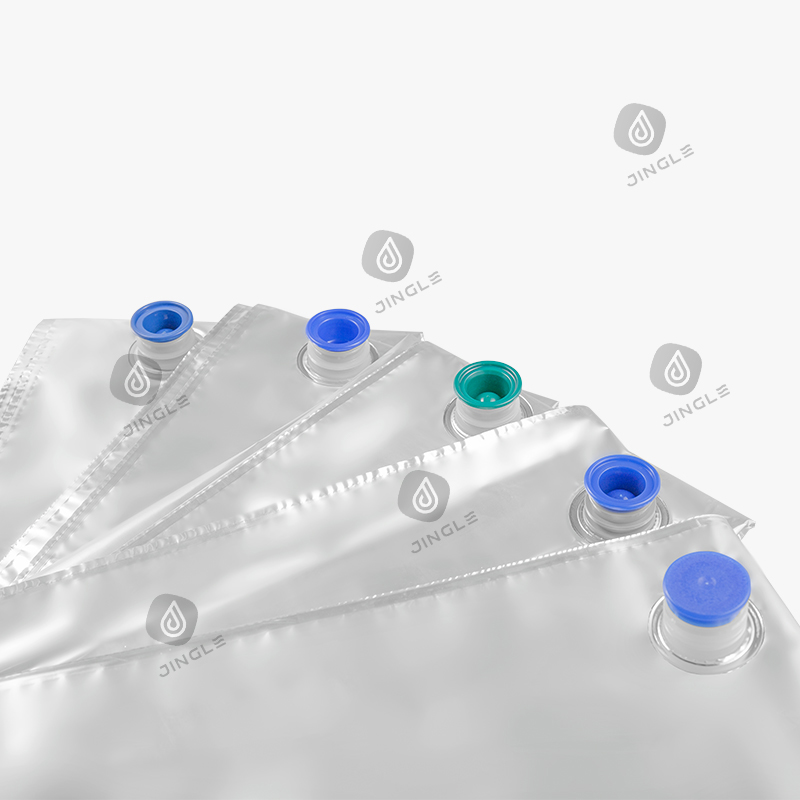

4. Selection of valves and accessories

Valves: Select high-quality plastic valves to ensure their sealing performance and durability. For example, a design with a one-way valve can prevent air from entering the package and extend the shelf life.

Tubes and accessories: Tubes and accessories need to be compatible with the packaging material to avoid leakage or chemical reactions caused by material mismatch.